Table of Contents

The convergence of mechanical engineering and IoT (Internet of Things) technology is reshaping Brunei’s industrial landscape, marking a significant shift toward Industry 4.0. As the sultanate continues its economic diversification efforts, the integration of smart systems in industrial applications, while ensuring quality assurance, has become increasingly crucial for maintaining competitiveness in the global market.

Current Mechanical Engineering and IoT Landscape

Brunei’s industrial sector has traditionally relied on oil and gas production, but recent developments show a growing adoption of IoT-enabled mechanical systems across various manufacturing facilities. These smart systems combine traditional mechanical components with advanced sensors, data analytics, and network connectivity to create more efficient and responsive industrial operations.

Predictive Maintenance and Equipment Optimization

The implementation of IoT in mechanical systems has brought remarkable improvements to predictive maintenance practices. Local industries are now equipped with sensors that continuously monitor equipment performance, vibration patterns, and temperature variations. This real-time data collection enables maintenance teams to identify potential issues before they escalate into costly breakdowns, significantly reducing downtime and maintenance costs.

Energy Management and Sustainability

Energy efficiency has emerged as another key benefit of IoT integration in Brunei’s industrial sector. Smart systems monitor and optimize energy consumption patterns, allowing facilities to adjust their operations based on demand and peak usage periods. This has particular relevance for Brunei’s commitment to sustainable development and energy conservation goals, while simultaneously reducing operational costs for businesses.

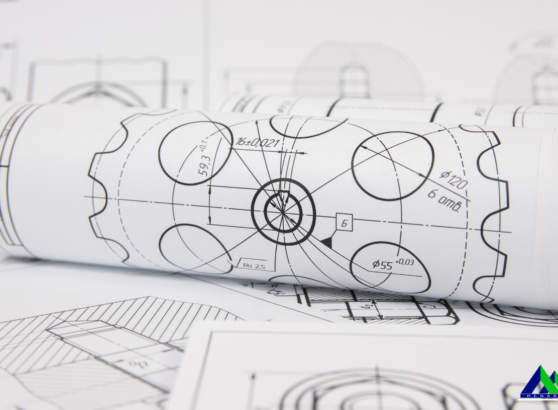

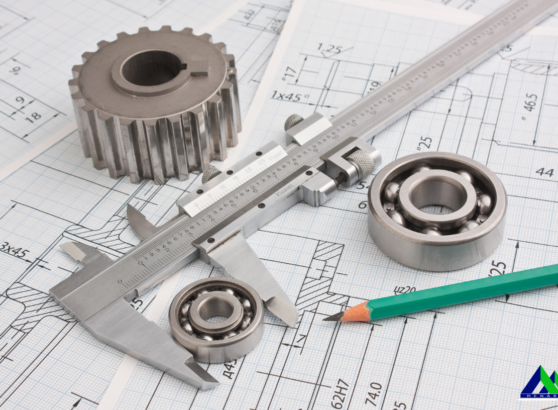

Quality Control and Manufacturing Excellence

Manufacturing processes have also seen substantial improvements through the implementation of IoT-enabled quality control systems. Advanced sensors and machine learning algorithms work in tandem with mechanical components to detect product defects in real-time, ensuring higher quality standards and reduced waste. This level of automation and precision has helped local manufacturers meet international quality standards while maintaining competitive production costs.

Workforce Development and Education

The adoption of these technologies has created new opportunities for Brunei’s workforce. Local engineers are developing expertise in both mechanical systems and IoT technologies, creating a new breed of professionals capable of designing, implementing, and maintaining smart industrial systems. Educational institutions in Brunei are responding to this trend by updating their curriculum to include IoT and smart systems engineering courses.

Enhanced Safety Protocols

Safety protocols in industrial settings have been enhanced through IoT integration. Smart sensors monitor environmental conditions, equipment status, and worker safety parameters, triggering immediate responses to potential hazards. This has resulted in improved workplace safety standards and reduced incident rates across Brunei’s industrial facilities.

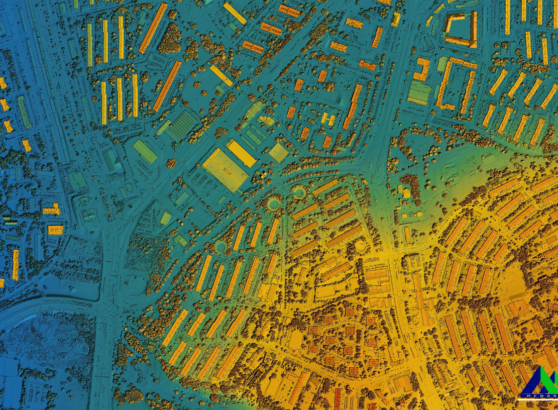

Data Analytics and Decision Making

Data analytics plays a crucial role in these smart systems, providing valuable insights for decision-making processes. Industrial facilities can now track production metrics, energy usage, and equipment performance in real-time, enabling managers to make data-driven decisions that optimize operations and reduce costs.

Future Prospects and International Collaboration

Looking ahead, the future of mechanical engineering and IoT integration in Brunei shows promising potential. As more industries embrace these technologies, the demand for smart systems continues to grow. This technological evolution aligns with Brunei’s Vision 2035, which emphasizes economic diversification and technological advancement.

Conclusion

The success of IoT implementation in Brunei’s industrial sector has attracted international attention, leading to increased collaboration opportunities with global technology providers and manufacturing experts. This exchange of knowledge and technology is helping to establish Brunei as a regional hub for smart industrial solutions.

As Brunei continues to develop its industrial capabilities, the integration of mechanical engineering and IoT will play an increasingly important role in shaping the future of manufacturing and industrial processes. The ongoing digital transformation of traditional mechanical systems represents not just technological advancement, but a fundamental shift in how industrial operations are conceived and executed in the sultanate.