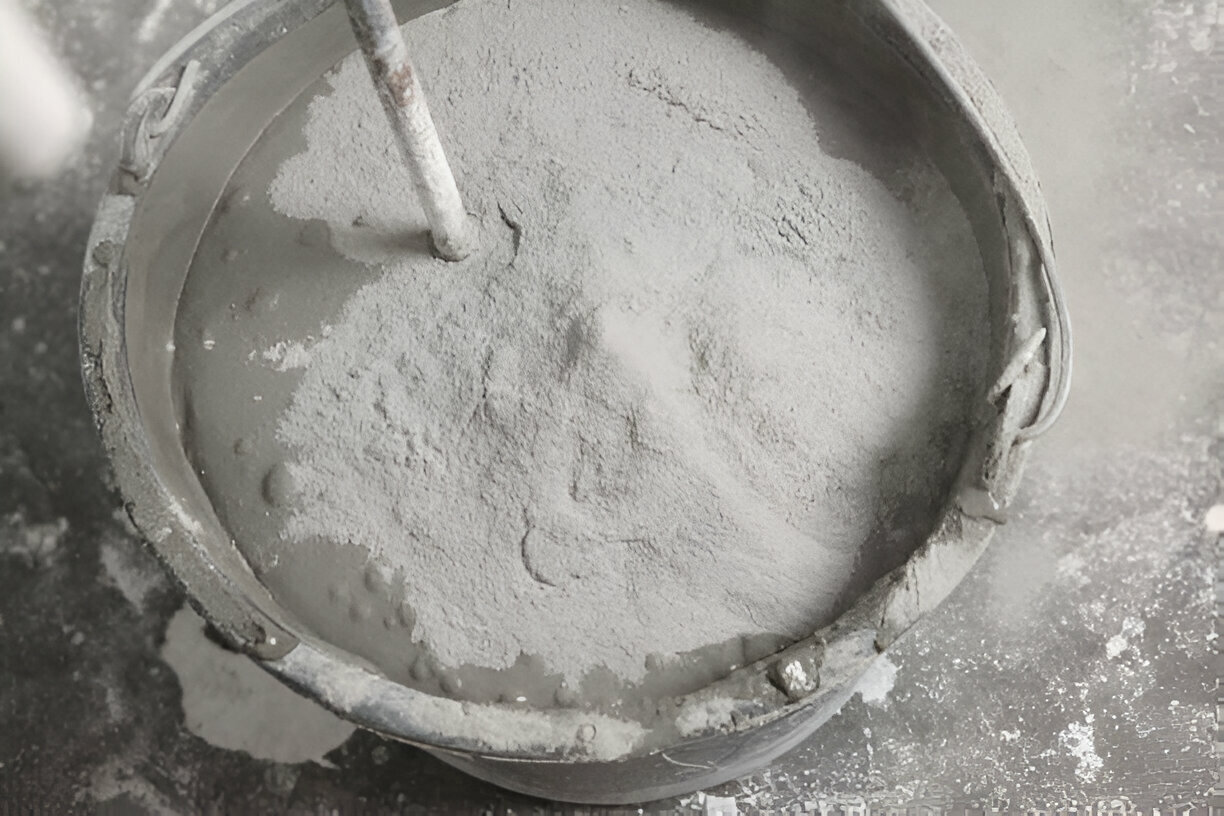

Getting the concrete mix just right is essential for making structures last and work well. This means picking the best mix and materials to make concrete strong enough to handle big loads and tough conditions. Also, a good mix design ensures the concrete lasts long, even with things like freezing and thawing, chemicals, or rubbing against things.

This is really important, especially for big projects like bridges or dams. Different mixes are available for different needs, like super-strong concrete for big structures or lightweight concrete for buildings. With the right mix design, structures can stay strong and safe for a long time, saving money on fixes and keeping people safe.

Top 6 Concrete Mix Designs for Strength and Durability

Normal Strength Concrete Mix:

Normal-strength concrete mix is used in many construction jobs where super-strong concrete isn’t needed. It’s made of cement, sand, gravel, and water in just the right amounts to give it a compressive strength of about 2,500 to 6,000 pounds per square inch (psi). This mix is good enough for most home and business projects, like sidewalks, driveways, and small foundations.

High-Strength Concrete Mix:

High-strength concrete mix is made to be super strong, with compressive strengths higher than 6,000 pounds per square inch (psi). It’s made with less water than other mixes and sometimes includes extra stuff like fly ash or silica fume to make it stronger and last longer. This mix is perfect for big structures like bridges, tall buildings, and factories that need to handle heavy loads or tough conditions.

Self-Consolidating Concrete (SCC) Mix:

Self-consolidating concrete (SCC) is a special type of concrete that flows easily and evenly, filling up tight spaces and dense areas without needing to be shaken. It’s made with special chemicals that help it flow well. SCC is great because it’s easy to work with, saves on labor, and leaves a nice surface when it dries. It’s used for things like fancy architectural concrete, pre-made parts, and structures with lots of reinforcement.

Fiber-Reinforced Concrete Mix:

Fiber-reinforced concrete (FRC) is made with tiny fibers, like steel, glass, or synthetic ones, to make it tougher, better at resisting impacts, and control cracks. These fibers help stop cracks from forming and spreading, absorb more energy, and strengthen concrete. FRC is often used in places like factory floors, roads, tunnels, and sprayed-on concrete, where the concrete must last a long time and not crack easily.

High-Performance Concrete (HPC) Mix:

High-performance concrete (HPC) is specially designed to be stronger and last longer than regular concrete. It’s made with really strong cement, special chemicals, and carefully chosen rocks to make it tougher and better at resisting damage from tough conditions. HPC is often used in big projects like highways, buildings near water, and structures that need to keep dangerous stuff contained for a long time.

Ultra-High Performance Concrete (UHPC) Mix:

Ultra-high performance concrete (UHPC) is the top of the line in concrete tech. It’s super strong, lasts forever, and bends without breaking easily. It’s made with a super tight mix of small particles, really strong fibers, and special chemicals to make it super tough and able to handle lots of pressure. UHPC is used in really tough jobs like connecting bridges, making buildings withstand earthquakes better, and making fancy building fronts that need to look great and stay strong for a long time.

Conclusion

Picking the perfect concrete mix design ensures your construction projects last and stay strong. Knowing what each mix does is key if you need regular concrete for homes or super-tough concrete for special jobs. When choosing durable concrete mixes, you ensure your structures last a long time and work great.